Our Notes on Leather

WICKETT & CRAIG LEATHER

Sourced from North American cattle of European stock, our Wickett & Craig leather hides are tanned in the United States. The entire vegetable tanning process takes about two months.

Tanning

Before undergoing the tanning process, raw leather hides are split and rehydrated for a few days. The split hides then soak for several weeks in large vats of proprietary blends composed of natural tannins extracted from tree barks, including those of Mimosa and Quebracho.

Drum-Dyeing, Fat-Liquoring & Hot-Stuffing

Tanned hides then undergo color treatment known as drum-dyeing. After which they are fat-liquored with a rich mixture of conditioning oils and waxes to sustain the structural integrity of the hide's fibers and protein bonds. Our specific leather hides are further hot-stuffed, in which hides are impregnated to their core with a combination of nourishing waxes and tallows. Hot-stuffing allows for greater durability and deeper concentration of color.

Drying

Once tanned and nourished, the hides are then sammied, for moisture-distribution, and removed of wrinkles. The hides are subsequently air-dried for three days in a climate-controlled and dehumidified space. After which, the hides are staked to soften.

Finishing and Jack-Glazing

The softened hides are then waxed once more for protection. Finally, our leather hides undergo jack-glazing, a process where glass rods are used to burnish the hide's surface for a polished shine.

The Wickett & Craig tannery has been audited by the Leather Working Group for environmental certification.

GRADES OF LEATHER

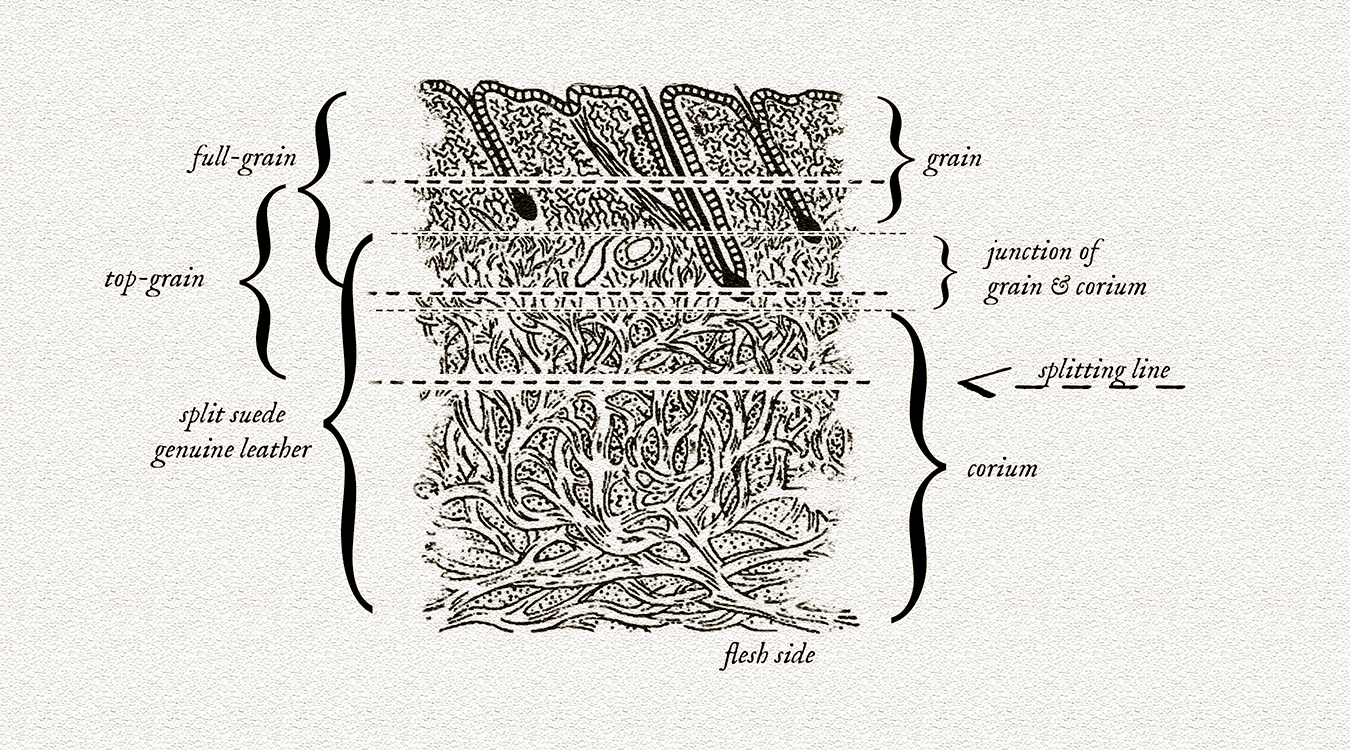

Full-Grain Leather

The premium grade of leather, full-grain hides have not been sanded, buffed, or snuffed to remove natural markings or imperfections. These hides retain their entire thickness. While sanding away the hide's top layer (which contains natural imperfections) may produce a more visually appealing surface, this crucial layer of natural grains contains the hide's strongest fibers, which constitute much of the hide's material strength and durability. Full-grain leather is also highly breathable, which prevents excessive build-up of moisture from prolonged contact. As full-grain leather ages, it naturally burnishes and develops a highly desirable patina, a characteristic that other grades of leather do not possess.

Top-Grain & Corrected-Grain Leather

A lesser grade of leather, a top-grain hide no longer contains the upper most layer of natural grains--this layer has been sanded away to remove imperfections and blemishes. If a substantial amount of grains has been sanded away, an artificial grain pattern may be embossed onto the surface. Top-grain leather comes from the top split of a hide (with the second and third splits classified as split suede or made into genuine leather), making it thinner and more pliable than full-grain (not split).

For uniformity, this type of leather is often treated with a protective coat of finish. This artificial finishing allows top-grain leathers to be more stain-resistant than their full-grain counterparts. At the same time, the finishing dramatically reduces breathability and makes impossible the development of natural patina. Top-grain leathers are most often used in the manufacturing of high-end handbags.

Split Suede or Genuine Leather

Split suede and genuine leather occupy the lowest grade of the three. Split suede is the second or third splits of the hide while genuine leather is manufactured by compressing and bonding together the leftover and less valuable layers of a split hide. Both sides of the split suede contain no grains and thus the corresponding fibers, making it much weaker than full-grain and top-grain leathers. In genuine leather, a synthetic layer is added to the surface and then imprinted with artificial grains.

TYPES OF TANNAGE

Vegetable Tanning

The vegetable tanning method uses tannins and materials found in plants-- leaves, roots, fruits, and barks. Commonly used tree barks come from oaks, chestnuts, mangroves, and acacias among others. A complex process, vegetable tanning is time-consuming and heavily-dependent on highly-skilled artisans.

Vegetable tanning creates leathers that can mold, stretch, breathe, and age with patina. Due to the natural ingredients used, vegetable tanned leathers are not uniform in appearance and can only be found in organic earthy shades. Thicker and much more rugged, vegetable tanned leathers hold up to daily use and can last for decades.

Hippolyte Dussauce, A New and Complete Treatise on the Arts of Tanning, Currying, and Leather-Dressing (1856).

Chrome Tanning

Chrome tanning involves soaking raw leather hides in a solution of Chromium Sulfate or other chromium salts. The tanning process can take as little as 24 hours. Thus, about 90 percent of leather worldwide today are chromium tanned. Chrome tanning produces leathers that are uniform in appearance, more water-resistant, much more pliable, and available in a wider range of colors. However, the chemicals used in chrome tanning cause discernible harms to the environment and the workers handling them.

Other less common or application-specific types of tannage include aldehyde tanning, rose tanning (rose otto oil), brain tanning (animal brains) and Chamois (fish oil).